2018:

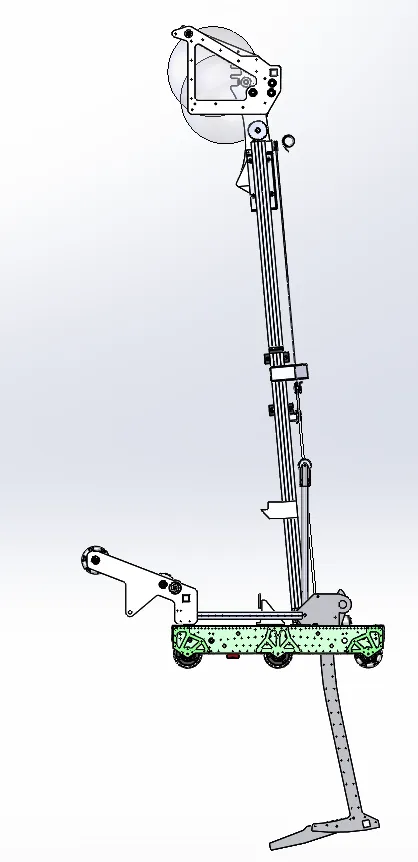

I assisted the design team on the elevator and system integration in 2018, using novel round tube and printed rollers to make an incredibly fast multi staged elevator. The elevator used chain for the first stage, then a nested string for the following stages. The elevator was strategically design to fit under the lowest ‘scale’ and to stack cubes 2 high on the highest scale. The elevator had to hold an intake mechanism and a hook for the lifting mechanism. We used a constant force spring to help the elevator ‘float’ reducing the load on the motors to just inertia when we werent picking up game pieces.

2019:

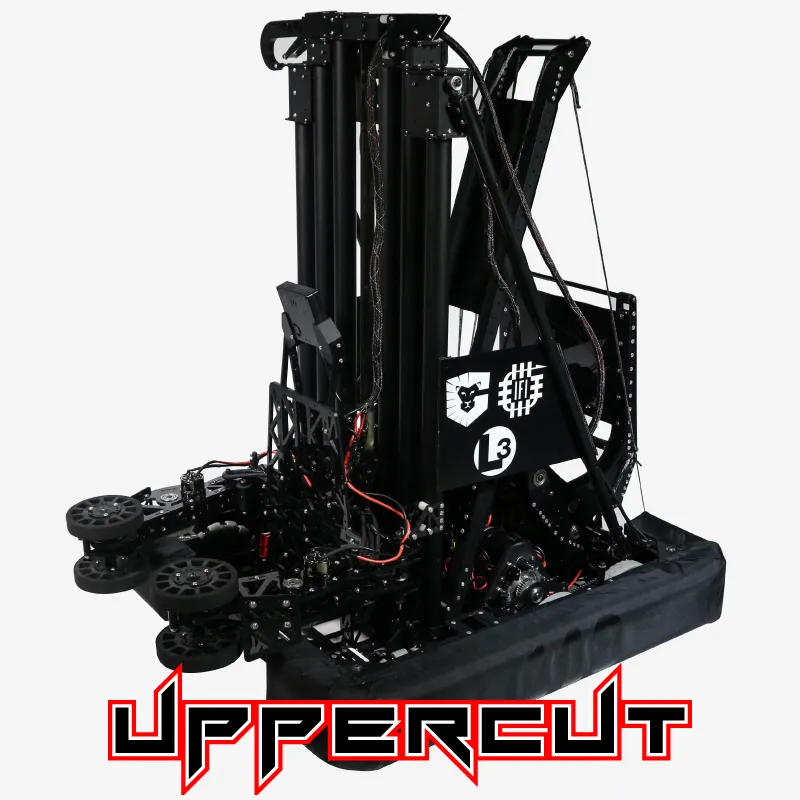

Me and a partner designed the lifting mechanism and assisted with system integration. We started with gas shocks that simply had to be actuated to release them. Our rocker style feet would allow the robot to shoot upward, fall forward and land on the highest pedestal without touching the bottom. This mechanism was reworked later since the robot would sometimes fall backwards. With a dedicated motor, we could raise the robot then drive forward and retract them in a much more controlled way. However, the mechanism was so iconic that it had a dedicated ‘blooper’ video at the end of our robot reveal, and inspired the robot’s name: Overhang. During the competition season, I was the go to for several key functions on the team. I soldered all of our custom sensor boards, most of the electronics and harnesses on the robot, was the designated “pnuematics person” and lathed many of the shafts and other parts used on the robot.

2020:

As part of our offseason after 2019 we made X19, a swerve drive test bot. I assisted the design team with integrating the COTS swerve modules with a new design method for the team. 148 had previously relied extensively on sheet metal construction, but X19 was a test of using aluminum extrusion and markforge printed brackets to adapt the different structural pieces. This design was a huge success and a great programming platform for the team leading into 2020. While I was lucky enough to help once again to design the drive, the turret, and system integration in 2020, the season was cut short due to covid.

2018 Robot in the Pits

2018 Robot Promo Shot

Early Lifter Mechanism from 2019